Tianyue Gao, Leanna Schulte, Langqiu Xiao, Eisuke Yamamoto, Amy S. Metlay,Colton J. Sheehan, Sariah Marth, Heemin Park, Sayantan Sasmal, Francisco J. Galang,Chulsung Bae, Adam Z. Weber, Shannon W. Boettcher, and Thomas E. Mallouk*

Abstract

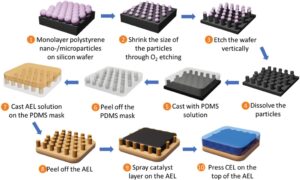

A soft lithographic method is developed for making bipolar membranes (BPMs) with catalytic junctions formed from arrays of vertically oriented microscale cylinders. The membranes are cast from reusable polydimethylsiloxane (PDMS) molds made from silicon masters, which are fabricated on 2″ to 4″ wafer scales by nanosphere lithography. High-aspect-ratio junctions are made on a length scale similar to the thickness of optimized catalyst layers for water dissociation, creating a platform for probing the dual effects of catalysis and local electric field at the microscale BPM junction. Optimized polymer materials and nanoscale metal oxide catalysts are used in this study. 3D BPMs are tested under reverse and forward bias conditions, exhibiting superior performance relative to their 2D counterparts. Under forward bias in H2-O2 fuel cells, 3D BPMs achieve a current density of 1500 mA cm−2, ≈7 times higher than 2D membranes made from the same materials.